Salt of

the earth

(or, in our case, the sea!)

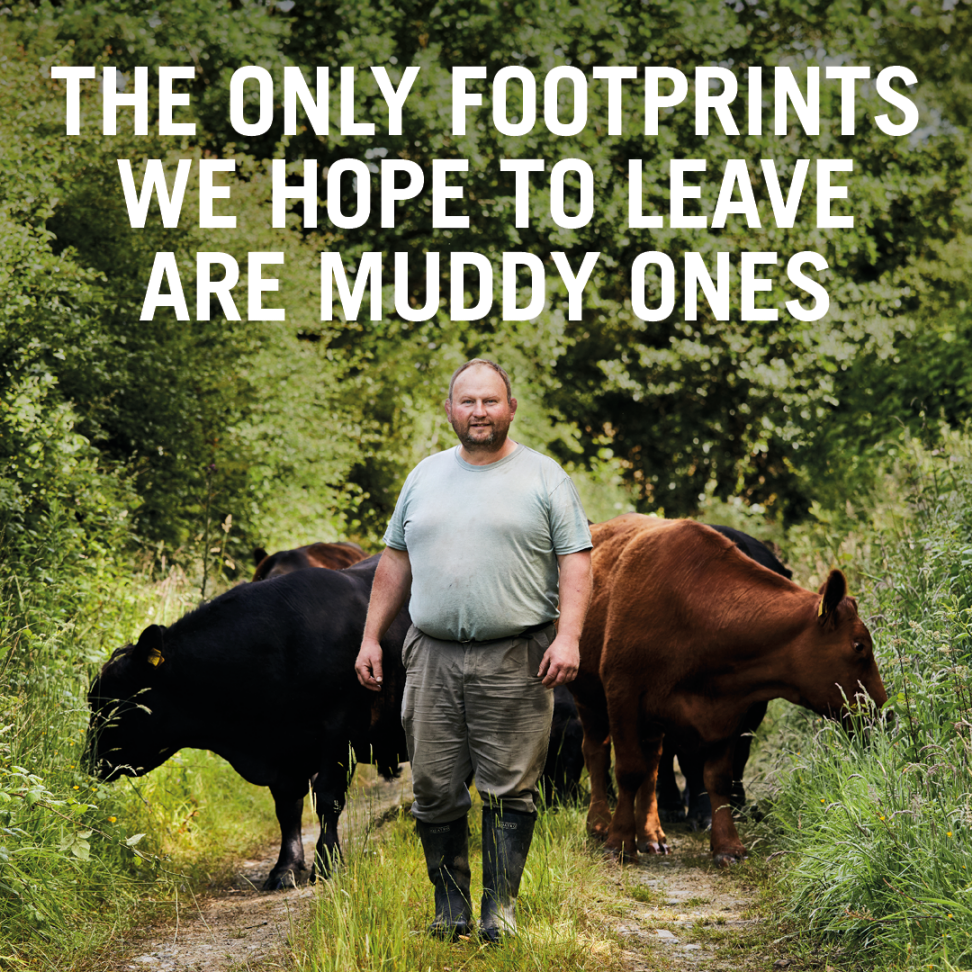

Our snacks are rustic, hearty, and full of flavour. They’re made with produce sourced from our fields to our fringes, and everything we do is about packing as much of what makes our county so special into every big crunchy handful.